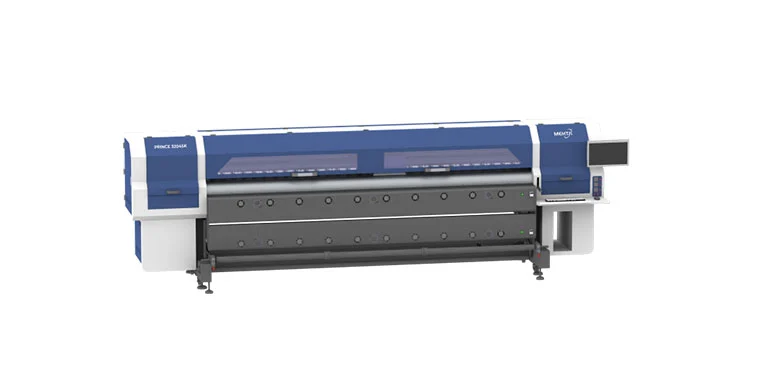

Digital Printer

Whether you work in a Digital Printers, Creative Agency or a Corporate Office, why settle for anything less when you can get MORE Creativity, MORE Simplicity, MORE Savings, and get MORE out of your business. Presenting the Canon image PRESS C265, a perfect combination of user-friendly interface and patented technologies that ensure professional quality to your color documents. iPR C265 will enable you to expand your business and move beyond the current realm of work. We are one of leading Digital Printers Manufacture in this industry.

- Print speed of up to 65/70 pages per minute (Color/Black & White)

- 350g/m² media weight support on manual duplex

- 2400dpi sharp image quality with image PRESS R-VCSEL Laser

- 1300mm long-sheet capability

Size of Paper:

- At the time of installing PF – 710: Undefined pattern paper (maximum 324× 483 mm, minimum 95 × 100 mm)

- Paper size (maximum 324× 463 mm, minimum 182 × 139 mm) When loaded with PF – 710 SRA 3, SRA 4, A 3, B 4, A 4, B 5, 133 mm)

Copy Magnification:

- Fixed Equal Magnification- 1: 1 ± 0.5% or less

- Fixed Expansion- 1: 1.154 / 1.224 / 1.414 / 2.000

- Fixed Shrinking- 1: 0.866 / 0.816 / 0.707 / 0.500

- Copy Magnification Fixed Optional- Three types can be set

- Copy Magnification Zoom- 25% to 400% (It can be set in 0.1% unit)

Image Loss:

- 3 mm or less for top edge, Max. 2 mm or less for bottom edge, Max. 2.0 mm or less for right/left edges

Corresponding paper basis weight:

- Standard: 40 gsm to 300 gsm (Limitations to paper types apply)

- PF-706 and middle tray of PF-709 : 40 gsm to 350 gsm (Limitations to paper types apply)

Duplex copy (print):

- Supported paper basis weight: 40 to 300 g / m2 SRA 3, SRA 4, A3, B4, A4, B5, A5 max: 324× 483 mm, min: 95 × 133 mm

Maximum power consumption:

4.0 kW (Device system value other than option equipped with dedicated power cord)

Mechanical installation dimensions:

Secure work space of more than 200 mm from the back duct and more than 100 mm on the left and right when 631 mm or more (when the main body ADU gantry is pulled out) on the front of the machine

Automated density correction · front and back register adjustment

- Implemented with high precision for a short time, skillless.

- It performs automatic density correction and front / back register adjustment before printing. It drastically reduces the adjustment time taken other than the original production time and contributes to improving the printing occupancy rate directly linked to profit. Also, manual measurement and numerical input as before are unnecessary. We will eliminate quality problems caused by measurement and input errors, provide skillless, high quality printed products.

Real time gradation correction · front and back register adjustment

- Monitoring and correction in real time during printing

- Automatically write gradation patches and registration marks in the margin of the printed matter, continue monitoring without decreasing productivity during printing. When a deviation from the target level is detected, it automatically corrects, suppresses the occurrence of cracks, contributes to cost reduction and improvement of customer reliability.

Belt transfer method

- Improve transfer quality and conveyance of paper.

- Tightly adhere paper to the belt to eliminate gaps, uniformly adhere toner uniformly by the pressure of the belt. Minimize transfer misalignment caused by missing images on the paper edge and resistance of the roller.

High-accuracy front and rear register adjustment function

Add image rotation and skew correction

It corresponds also to the adjustment of the rotation and skew of the image, making it possible to adjust the front and back register more accurately. Easier adjustments can be made to applications requiring high front / back register accuracy, such as business cards, shop cards, tickets.