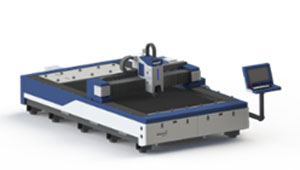

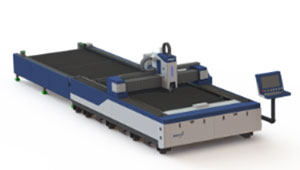

Fiber Laser Metal Cutting Machine

High precision Fiber Laser Metal Cutting Machine is specially designed for pipes, easy to operate. With the good cutting quality and cutting efficiency, the Fiber Laser Metal Cutting Machine is widely used in sports equipment, various types of pipe, water pipes, oil pipelines and other industries, and adapted to various special-shaped pipe materials such as: round pipe, square pipe, rectangular pipe, oval pipe, etc. JAYITA CAD CAM SYSTEMS is a reputed Fiber Laser Metal Cutting Machine Manufacturer in Kolkata.

Description:

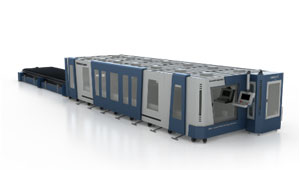

- High precision Fiber Laser Metal Cutting Machine

- Digital chuck, intelligent and multi-functional

- Wide Scope of Application, No Worry about Special-shaped Tubes

- High precision Fiber Laser Metal Cutting Machine is specially designed for pipes, easy to operate. With the good cutting quality and cutting efficiency, the Fiber Laser Metal Cutting Machine is widely used in sports equipment, various types of pipe, water pipes, oil pipelines and other industries, and adapted to various special-shaped pipe materials such as: round pipe, square pipe, rectangular pipe, oval pipe, etc.

Clamp Design

Precise pneumatic double-acting chuck, with automatic center adjustment, high precision, low inertia, and heavy load-bearing functions. The diagonal adjustable range is 20-350mm

Professional pipe cutting system

It supports high-precision and high-efficiency cutting of square tubes, round tubes, racetrack-shaped, elliptical and other stretched tubes, as well as angle steel and channel steel.

- Real-time core deviation compensation

- High precision realization of perforation

- Support corner crafting individually set

- Support advanced technology such as cooling point, sharp corner ring cutting, release corner, etc.

The segmented rectangle tube welded bed

Good rigidity, high precision, no deformation during the life cycle: Welded aluminum collet chuck formed through high precision process. Good weight and good dynamic performance

Front And Rear Automatic Self-centering Pneumatic Chuck

Tube laser cutting machine can realize the possible size and shape feature processing of the complicated tube structure like cutting.chamferinq, grooving or hole, scoring and other.

Front and rear dual pneumnatic chucks, maximum clamping diameter 220mm. The chuck comes with a self-centering function which makes it more convenient for pipe clamping and self-centering. reducinq manua clamping centering errors

Features:

- High rigidity heavy chassis, reducing the vibration generated during the high-speed cutting process.

- Gantry double-drive structure,with imported rack & gear transmission system, which improves the production efficiency.

- High-performance cast aluminium guide rail, after infinite aalysis ,which accelerates the cicular arc cutting speed.

- Open worktable, easy operation and small space occupation.

- High precision, fast speed, narrow slit, minimum heat affected zone, smooth cut surface and no burr.