Static Table

| Auto camera position system | High Speed Oscillating Tool |

| For cutting printed material automatically with high precision. | Cut the material smoothly in high speed. |

| Safety of operating personnel | High-precision |

| Inline with international standards of infrared anti-collision device ensure the safety of operating personnel. | High-precision,high speed Japanese brand servo motor. |

| Conveyor table | Suction holistic |

| Cutting the material without stop table move automatically improving the work efficiency. | Suction holistic approach to ensure cutting accuracy. |

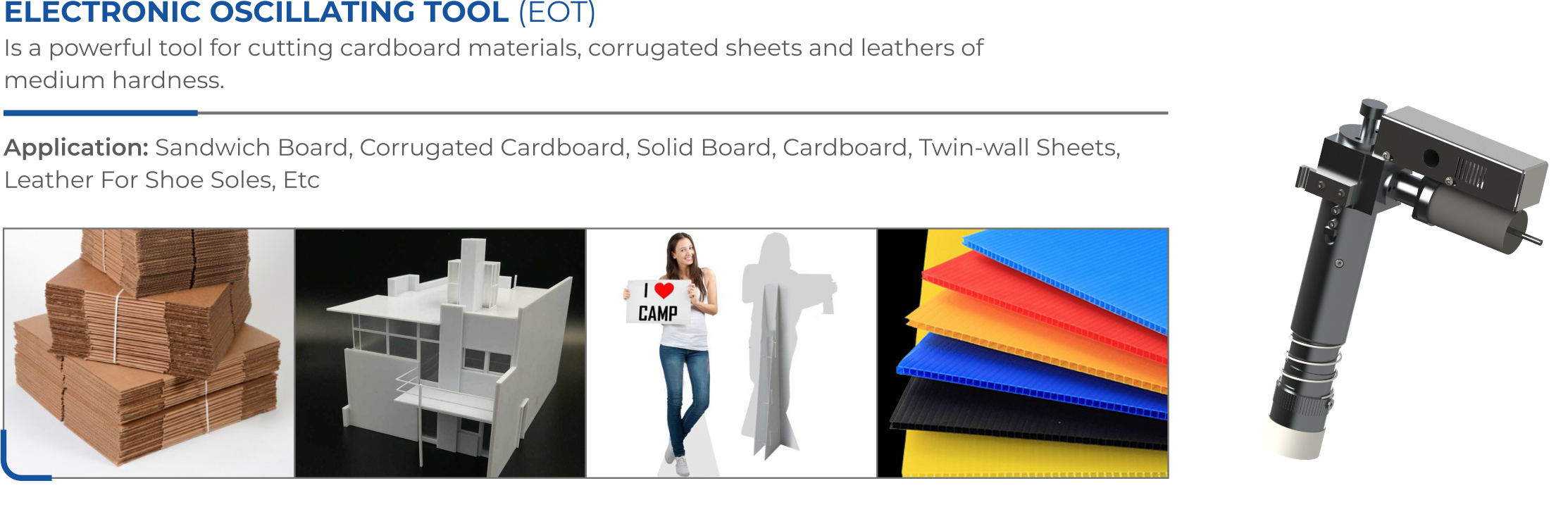

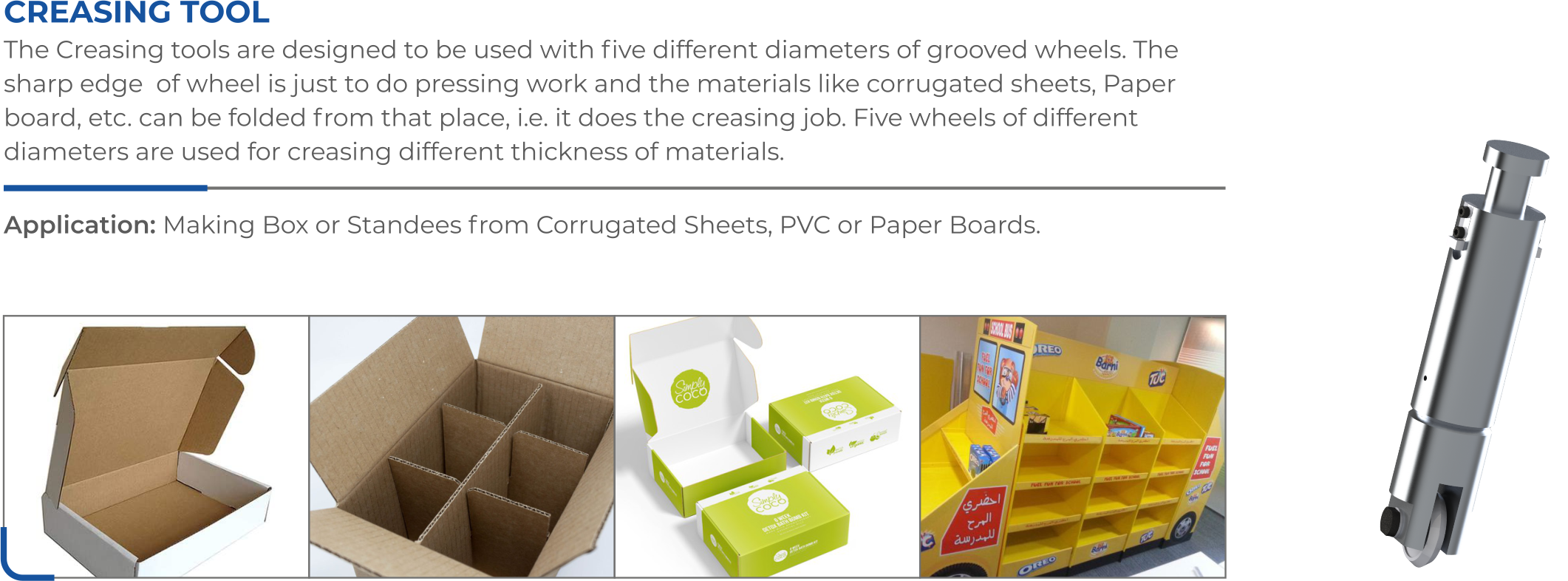

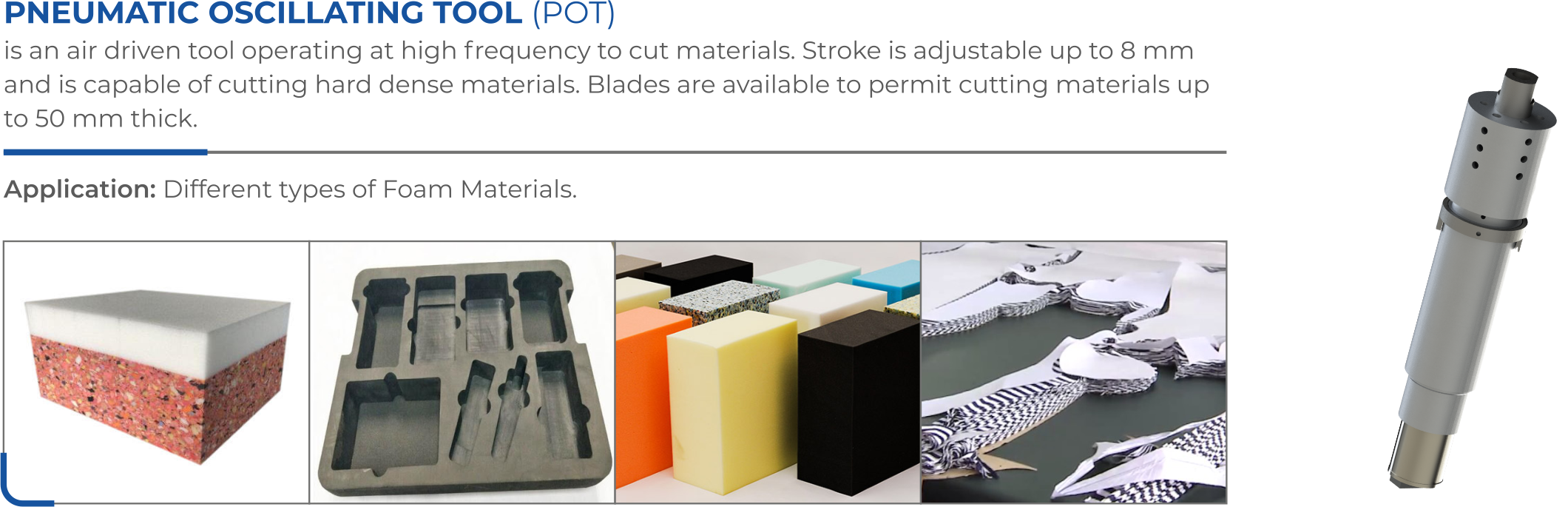

| A variety of optional tools: Oscillating tool | Automatic Feeding System |

| Oscillating tool, Creasing Wheel Kiss-cut, V-cut, Foam cut, Milling Cut, Circular Cut Etc.. | Automatic Feeding System (optional) |

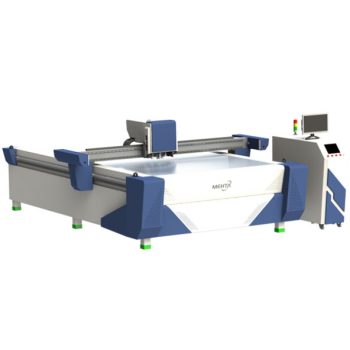

Model | REX 1325 | REX 1832 | REX 2530 |

Effective Cutting Area | 1300 x 2500 mm | 1800 x 3200 mm | 2500 x 3000 mm |

Machine Power | 4 KW | ||

Suction Power | 8.6KW / 12KW | ||

Operation Properties | Work with computer synchronously for quick data transmission, multi-page file in one time | ||

Max. Cutting Speed | 0-1400 mm/s | ||

Cutting Thickness | ≤50 mm | ||

Cutting Materials | Corrugated board, Plastic Corrugated Board, Thick Grey Cardboard, PVC Sheets, Foam Board, EVA Board, KT Board, Adhesive Sheet, Gasket, Leather Etc. | ||

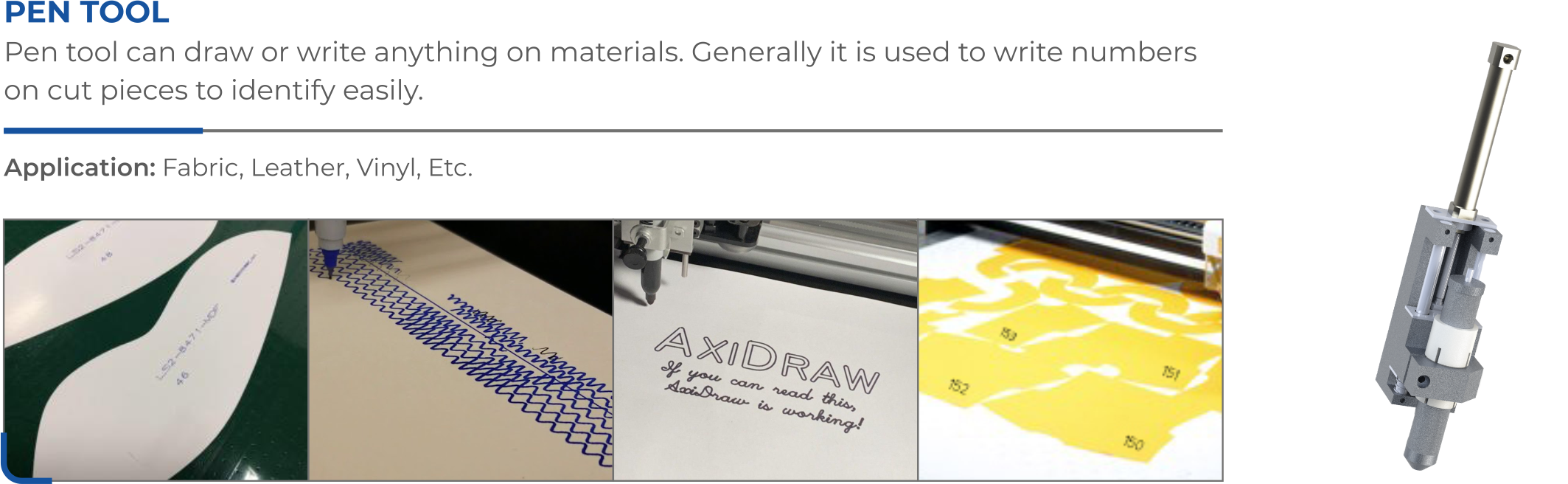

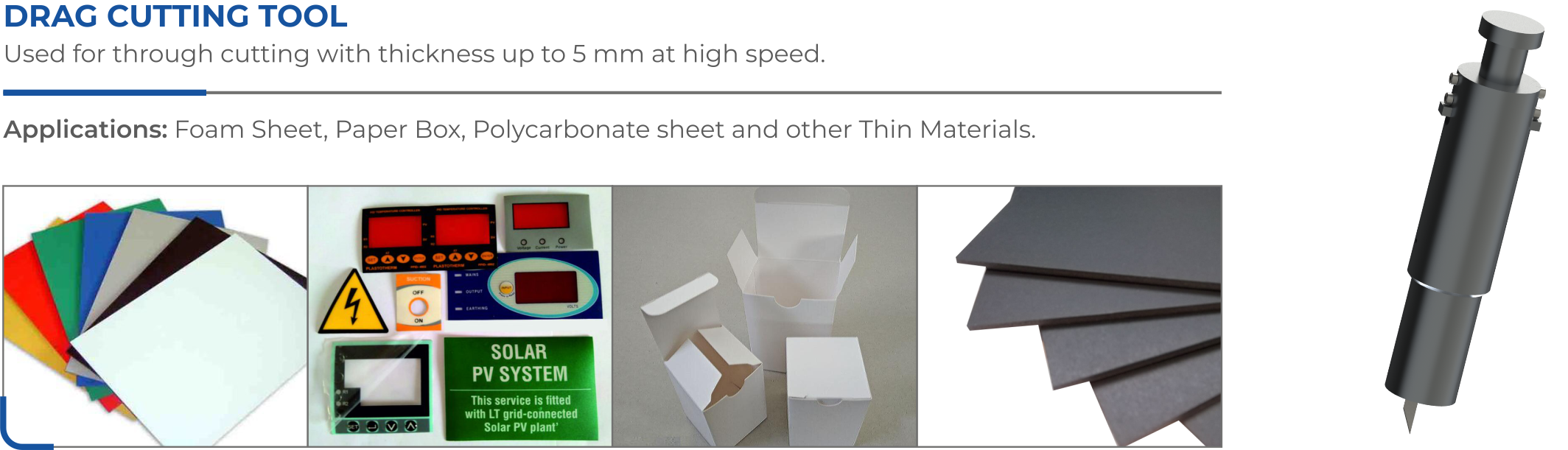

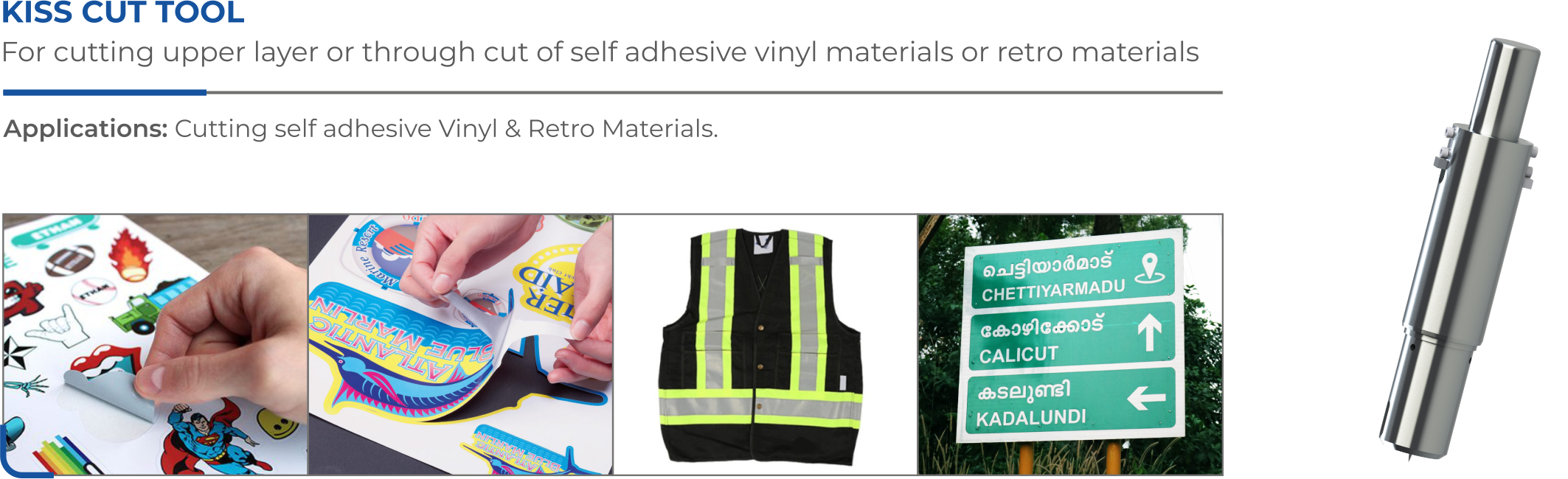

Standard Tools | Electronic Oscillating Tool (EOT), Electronic Oscillating Tool Heavy Duty (EOT-H), Creasing Tool, Pneumatic Tool (POT), Drag Cutting Tool, Kiss Cut Tool, V-Cut Tool, Driven Rotary Tool, Pen Tool, Spindle Tool, Glass Cutting Tool | ||

Option | Creasing Wheel, Foam Cut, V-Cut, Milling Tool | ||

Fixing Method | Vacuum Suction | ||

Repeat Precision | ≤0.01 mm | ||

Software Resolution | 0.025 | ||

Interface | Ethernet Port | ||

Buffer Memory | Fast Transmission for Multi-Page Large File | ||

Command Mode | HP-GL Compatible Format | ||

Format Compatible | Like any CAD Software, Like AI / CorelDraw / AutoCAD Etc | ||

Control Panel | 7 Inch Colour Touch Screen | ||

Driving System | Digital Servo Motor, Straight Rail | ||

Voltage / Power | AC 380V±10% 50HZ | ||

Fuse | 6A / 30A | ||

Specifications are liable to change without prior notice. All trademarks mentioned are property of their respective owners. | |||

+91 9051833747 / +91 9021228015